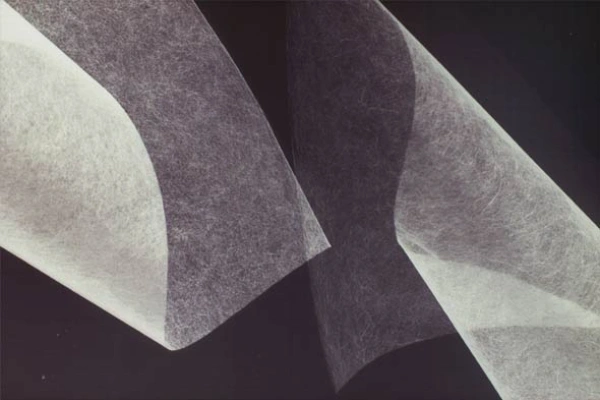

To obtain a smooth and polished surface and also increase corrosion resistance and prevent parts from being destroyed in the composite industry, tissue glass fibers are used as the first layer on the surface of the part. Due to their thinness and easy formation in the mold, these fibers prevent air and bubble formation when applying the gel coat and prevent the surface of the composite part from blistering.

Applications of tissue fibers

By using these fibers to produce barges, boats and other parts that are in humid, water and sunlight environments, the corrosion resistance of the composite part is increased.

Your comments

Comments

There are no reviews yet.